series Explosion-proof travel switch

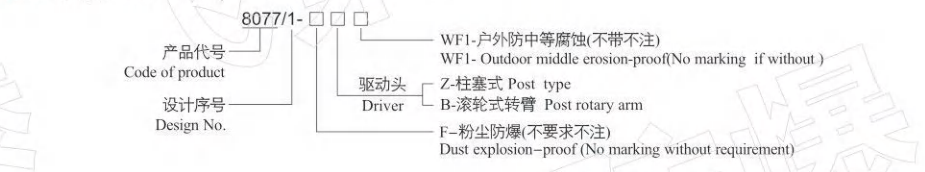

Model Implication

Features

1. The outer casing of the product is cast aluminum alloy ZL102. Adopting a one-time die-casting process, the surface is smooth, the appearance is beautiful, the internal structure is dense, the impact resistance is strong, and the product has a permanent “Ex” explosion-proof mark.

2. After the surface of the product is deburred by industrial robots and high-speed shot blasting, the advanced automatic high-pressure electrostatic spray and heat-curing line technology is adopted. The plastic layer formed on the surface of the shell has strong adhesion and good anti-corrosion ability.

3. The product is an explosion-proof explosion-proof enclosure with a special explosion-proof stroke switch module.

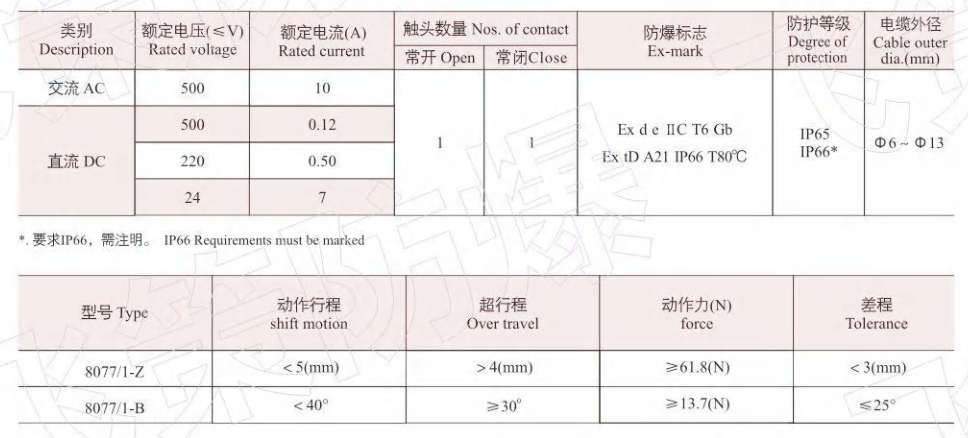

4. According to the driving head action form, it can be divided into: plunger type and roller arm type. Customers can choose according to their needs.

5. The sealing strip adopts two-component polyurethane primary casting foaming process with high protection performance.

6. All exposed fasteners are made of stainless steel.

7. Steel pipes and cable wiring are available.

Main Technical Parameters

Order Note

Please indicate the details of product model,,size, Ex-mark and quantity according to model implication and model selection table.